- A

- A

- A

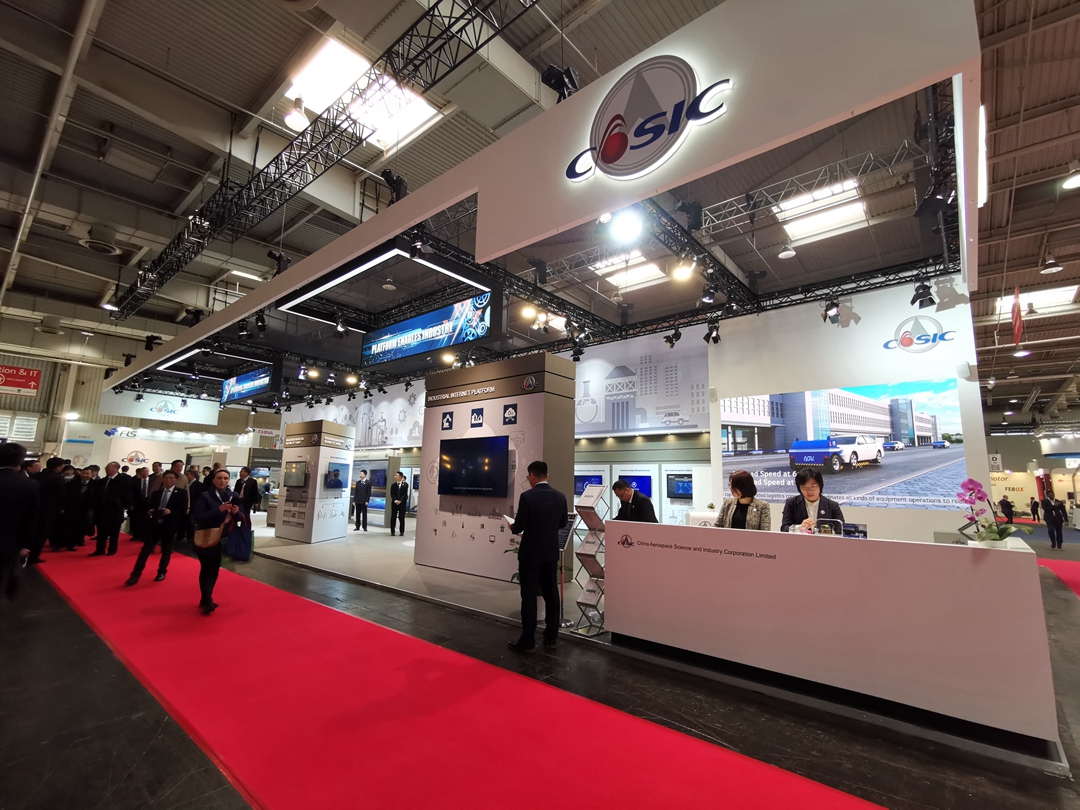

One platform, two exhibition sections, third-time participation, 47 exhibits, several promotion and commercial trade activities, dozens of products in manufacturing industry, a series of solutions...the 2019 HANNOVER MESSE officially kicked off on April 1. China Aerospace Science and Industry Corporation Limited (hereinafter referred to as CASIC), representing the full image of the enterprise, has made its appearance on this fair three times in a row, with 47 project products for two exhibition sections themed on “platform enables industry” and “upgrading through innovation” centering on the theme of the fair “industrial integration---industrial intelligence”. It has shown great successful examples of industrial Internet platform enabling traditional industries and promoting transformation and upgrading, and exhibited a series of new technologies, products and applications based on innovation and upgrading in the high-end equipment manufacturing field to interpret in depth its exhibition theme of “platform enables industry and upgrading through innovation”.

One platform: Industrial Internet Platform Enabling Traditional Industries and Promoting Transformation and Upgrading

It is the third time in a row for CASIC to showcase its industrial Internet platform on this fair. Compared with the former two participations, more exhibits were unveiled this time to comprehensively, systematically and specifically show how the industrial Internet platform enables traditional industries and promotes transformation and upgrading. By use of the multimedia system, the access capability, fusion capability, operation capability and ecosystem building capability of the platform were introduced to visitors, as is the INDICS + CMSS core configuration, building and maintenance of the ecosystem for cloud manufacturing industry clusters based on the industrial Internet, and achievements made in realizing digital transformation and upgrading of modern manufacturing industry.

CASIC showed a series of examples for actual application of the industrial Internet platform. The rich data, graphics and video clips on nine screens systematically showed real operation of the prototype room of electric coupler intelligent factory jointly built by CASIC and Siemens. The intelligent manufacturing prototype room is equipped with a set of collaborative manufacturing system of a whole value chain. It effectively integrates the software and systems of downstream and upstream enterprises on the value chain, forms a longitudinal link that covers research and development, design, resource planning, manufacturing and operation, and other parts of the value chain, and realizes data-driven multi-variety small-batch flexible production with mixed production lines.

In addition, CASIC will also give an example of INDICS-based demonstration online cloud system of digital enterprises of Siemens. This example is based on advanced technologies such as finite-capacity optimization and scheduling technologies, production line digital twin technology and so on in intelligent manufacturing fields. It covers all links of the whole industrial chain including operation analysis, equipment and quality analysis, resource allocation and optimization, production operation management, and marketing, and reflects the cloud manufacturing ecosystem integration and other scenarios in a centralized manner. It can be used widely in a variety of manufacturing enterprises.

According to relevant information sources, the industrial Internet platform as a comprehensive production service platform with INDICS+CMSS as its core can provide intelligent manufacturing, collaborative manufacturing and cloud manufacturing public services for global users. As stated by Gao Hongwei, Secretary of the Party Leading Group and President of CASIC, it is a global consensus that nowadays the industrial Internet is leading a new trend of manufacturing industry and economic development and promoting fusion of new-generation information technologies and manufacturing industry will remarkably empowering the manufacturing industry and realizing its fundamental transformation.

Ever since it was officially launched in 2015, CASICloud has evolved into a national-level cross-industry and cross-field industrial Internet platform of China through four years of trial operation. It has provided free beneficial services and personalized value-added services for various enterprises, promoted building of ecosystems for cloud manufacturing industry clusters in “nine cities of seven regions” of China, and set dozens of examples for flexible production, collaborative manufacturing and intelligent transformation, enhancing deep fusion of new-generation information technologies and the manufacturing industry.

At present, a multilingual environment has been built for the international cloud platform CASICloud with such foreign versions as English, German, Russian, Spanish, French and Arabic being developed, launched and used in several countries and regions. In 2018, CASIC took the lead in formulating the first international standard oriented at intelligent manufacturing service platforms.

Two Exhibition Sections: Displaying Several Technologies, Products and Applications in The Manufacturing Field

Centering closely on the theme of the fair “industrial integration and industrial intelligent”, CASIC participated in the exhibition with 47 project products for two exhibition sections themed on “platform enables industry” and “upgrading through innovation” and intensively displayed several technologies, products and applications in the manufacturing field.

In the exhibition section of “platform enables industry”, CASIC showed the industrial Internet platform, industrial IOT solutions, intelligent manufacturing, energy management and water management; demonstrated level by level and in great detail the platform concepts and integral framework as well as project products and solutions in specific fields; fully showed examples of industrial Internet platform effectively supporting intelligent transformation, and key scenarios in which man-machine collaboration is seen during digital transformation.

On the site, COSIM (collaborative simulation) platform, the solution for research and development of virtual prototypes of complicated products, was exhibited. As the “treasure box” for research and development of complicated products, it is an integrated intelligent platform that supports multi-disciplinary virtual prototype modeling, development, simulation operation, evaluation and management in the full life cycle of complicated products.

The electrical cable intelligent manufacturing (ECIM) platform provides a solution for the whole process from design to manufacturing of electrical cables. With this platform, the following can be realized: high-efficiency automation design of electrical drawings, three-dimensional electromechanical collaborative design of electrical cables, collaboration of electrical design and process design, and visualized three-dimensional electrical cable manufacturing. This platform can also be seamlessly connected with the enterprise manufacturing information management system to realize digitalized management and control of the full life cycle of electrical cables from design to manufacturing.

By showcasing the IOT system, real-time embedded operating system, equipment monitoring and management system (cloud intelligent + cloud straight), it provides IOT solutions for multiple fields.

The electronic product intelligent manufacturing project displayed by AC Company, CASIC’s affiliate in France can realize high degrees of automatic, intelligent and flexible control. By use of this solution, AC Company has become a world leader (PPM<2) in terms of its automotive electronic manufacturing services and quality, earning much recognition of global customers.

Additionally, through such examples as the energy-saving management system for the thermal power plant of Finland, Siemens motor health management and digitalized operation and maintenance, thermal efficiency management system, and water integration management and control platform, CASIC has showcased the capacities of its INDICS platform in improving equipment automatic, digital and intelligent capacities and promoting data fusion and business circulation in the aspects of energy management and water management.

In the exhibition section of “upgrading through innovation”, CASIC specifically showed advanced equipment, special materials and intelligent solutions (22 items in total) researched in the fields of special equipment, intelligent detection, monitoring equipment, new materials and processes, intelligent logistics and intelligent life.

Among the special equipment, the artificial island oil & gas drilling rig is a kind of large equipment used for oil & gas drilling on artificial islands built in the shallow sea area. It is suitable for large scale exploitation of oil and gas in the shallow sea area, and can greatly reduce both cost and risks of marine oil and gas exploitation. The heavy flat truck, as special heavy transport equipment, has a carrying capacity of 35 t to 1,000 t and can be used by combination of two or more vehicles. It is widely used in such fields as ship manufacturing, marine engineering, petroleum engineering, aerospace, nuclear power, wind power and metallurgy.

Moreover, intelligent logistics products like the AGV-based intelligent logistics system, intelligent self-service terminal products like the intelligent cash register and new materials and processes like materials based on the additive manufacturing technology were also unveiled on this trade fair, which showcases in a centralized way CASIC’s efforts in improving technologies, products and applications used in human production and life.

Third Participation: from “Making a Debut”, “Making Big Strides” to “Standing out”

In 2017, CASIC made its debut on the HANNOVER MESSE with a total of 48 exhibition items for three technical exhibition sections of “intelligent manufacturing”, “industrial Internet” and “equipment manufacturing”; in 2018, CASIC further expanded its exhibition scale to about 70 products and solutions for five technical exhibition sections of “industrial Internet and intelligent manufacturing”, “intelligence and security”, “special equipment”, “new materials and fundamental industrial components” and “environmental protection technology”, providing precious opportunity for CASIC to promote its brand and project products and enhance communication and cooperation with relevant partners, and helping CASIC to improve its corporate reputation and influence.

In 2019, CASIC, representing the full image of the enterprise, participated in the HANNOVER MESSE for the third time in a row. Centering on the theme of the fair, CASIC selected suitable projects, products and solutions for exhibition on site and designed a vivid way of exhibition through interaction and interconnection of the exhibitor and visitors to further showcase the enterprise image of CASIC and promote its development concepts of “sharing information and resources, collaborative development, open cooperation, mutual-beneficial and win-win partnership”.

On this fair, CASIC vividly demonstrated multiple project products and solutions with nearly 20 video clips and dynamic PPT slides rich in content. During the exhibition with interaction involved, a series of smart card printing equipment with high-quality printing heads were showed. They can optimize printing and card feeding control processes and realize high-speed card printing. The erasable printer can realize repetitive printing of card information. This applies to patient ID cards, pass cards and other cards whose information changes periodically. A single card can be erased repeatedly for hundreds of times at the maximum. Another heavy-load smart card printer, based on industrial-grade design, can realize long-term printing and provide high-definition color cards. Visitors on site can get their facial information recorded through the camera at the booth and experience printing effects of different equipment. Smart card printers have been 3C- and CE-certified and can be used in case of instant card printing, which compared with traditional card printing methods, have greatly shortened the card printing time and is suitable for convenience service applications to improve efficiency.

During exhibition, CASIC together with dozens of its lower-level exhibitors continuously and intensively held several activities for promotion of the INDICS international industrial Internet product, AGV-based intelligent logistics system and so on; visited and received visitors from such international enterprises as Siemens and business delegations of Dresden, Germany and discussed cooperation with them to learn from each other and promote economic and trade cooperation between each other.

Wei Yiyin, a member of the Party Leading Group and Deputy General Manager of CASIC, stated that the third participation of CASIC is to: First further learn from and understand the development achievements and experience of world first-class enterprises in the industrial field by using HANNOVER MESSE as the international arena for exchanging thoughts, mutual learning and strengthening mutual understanding with peers around the world; second hopefully further promote the enterprise brand, image and development concepts of CASIC and assist international users in more conveniently sharing development achievements of CASIC; third expect to strengthen industrial technology and economic and trade cooperation with global elites from all walks of life so as to play an active role in promoting world economic development with joint efforts. (Written by Ke Xuan)